Highways: Fixing ageing geotechnical asset on A40 Brecon Bypass

Collaboration across design, construction and maintenance teams was crucial for the successful remediation of a landslide-damaged cutting on the A40 Brecon Bypass.

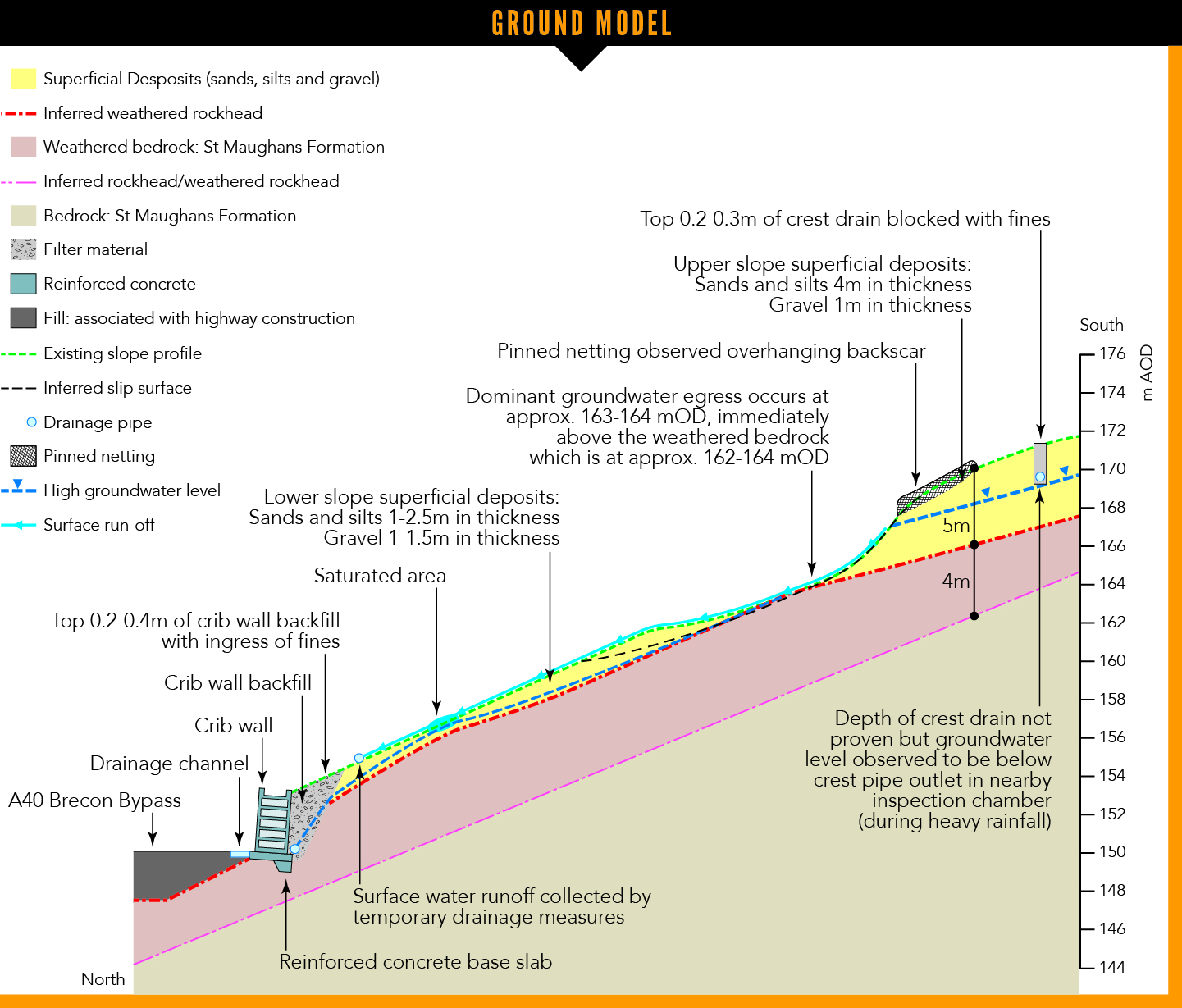

The A40 Brecon Bypass is a 4.2km long dual carriageway 1.5km south of Brecon, a town in mid-Wales. The road is largely constructed on sidelong ground in the Usk valley. The westbound cuttings are up to 23m high at up to 30° inclination and vegetated with trees. An up to 7m high cribwork wall is present at the cutting toe.

Following heavy overnight rainfall between 15 and 16 February 2020, a landslide occurred in the cutting. Around 400m east, a failure into a watercourse outside the highway boundary blocked a culvert, flooding the A40. After 300t of landslide debris were cleared within 48 hours of the failure, three lanes were reopened, while one westbound lane remained closed as part of the risk mitigation.

North and Mid Wales Trunk Road Agent (NMWTRA) commissioned Mott MacDonald to design the investigation and remediation of the landslide. The Welsh Government was the overseeing organisation for the CD 622 “Managing Geotechnical Risk” process, as defined in the Design Manual for Roads and Bridges’ (DMRB’s) geotechnical section.

Geotechnical Engineering undertook the ground investigation, and construction was carried out by Alun Griffiths.

GI and conditions

Mott MacDonald principal engineer Tom St John attended the initial inspections. “A 15m long, 3m high backscar was left by the failure, below which was a bowl,” he explains.

“At the cutting crest we identified a gravel drain covered by soil and vegetation. Surface water from third party land was flowing over the drain and onto the cutting.”

The mapped geology of the site comprises interbedded mudstone, siltstone and sandstone of the St Maughans Formation. No superficial deposits have been mapped; however, clayey gravelly sands and silts were exposed in the backscar.

The landslide took place following heavy overnight rainfall between 15-16 February 2020

The investigation also identified bedrock exposures in the bowl, as well as observing groundwater egress at the soil-bedrock interface. It was flowing downslope and over the wall.

“As-built drawings dated 1980 show a crest filter drain, slope netting and downslope drains either side of the landslide. Within the wider cutting, slope drainage, netting and rockfill layers are shown. We identified those features during site inspections and they indicate groundwater and slope stability challenges during the original design and construction,” St John adds.

Mott MacDonald engineering geologist Hana Oliphant assisted with the design of the interim risk mitigation and supervised the ground investigation.

“We undertook monthly inspections and established a rainfall threshold for further visits,” she says. “Reactive inspections were triggered when 70% of the seven day or 24 hour rainfall pre-landslide was exceeded. When vegetation was cleared, we found tension cracks either side of the backscar and installed a series of stakes. We monitored their offset and tilt to identify any movement.”

The team installed a temporary drainage channel and pipe to manage groundwater.

Ground investigations involved sinking nine dynamic sampling with rotary coring follow-on boreholes in October 2020.

Geotechnical Engineering contract manager David Owen says: “Sloping ground, a lack of crest access and the presence of a high retaining wall at the toe meant the use of traditional drilling equipment was not feasible. Utilising one of our P60 multipurpose slope climbing rigs ensured we collected critical design information in the area of the landslide, with crane lifts used to access over the wall during a night-time road closure.”

Geotechnical Engineering used crest anchors to support the rig in the event of loss of ground contact.

During the investigations, up to 5m of well graded sands and silts were encountered overlying extremely weak to medium strong mudstone and siltstone. The team installed dual-depth standpipe piezometers with dataloggers to understand the groundwater regime.

A rapid increase and subsequent decrease in groundwater level was observed following rainfall events for installations within the superficial deposits and fractured bedrock.

Geotechnical Engineering business development manager Jamie Darling notes: “Significant access challenges were overcome to collect accurate data to assist with the design and construction of the retention solution.

“Working collaboratively ensured restoration of the bypass to full capacity was achieved, as well as increasing resilience of the A40 against future geotechnical risk.”

Oliphant analysed the landslide preconditions, explaining that “99mm of rain fell between 15 and 17 February 2020 during Storm Dennis, compared to the whole-February average of 111mm”.

She continues: “Storm Dennis represents the second highest daily rainfall since the bypass construction, with Storm Callum in October 2018 representing the highest, at 106mm.

“One hundred and ninety nine millimetres of rain fell over a nine day period up to the end of Storm Dennis, compared to 151mm over the equivalent period to the end of Storm Callum.

“We found that higher daily rainfall had occurred at the site previously; however, we interpret that the cumulative antecedent conditions led to the landslide. The prolonged rainfall (the wettest February on UK record), large catchment, inefficient drainage and presence of the spring likely contributed to progressive saturation of the slope and initiation of the failure.”

Design development

The preferred fix for the site was an adaptable, robust and low-maintenance solution with extensive drainage works. Reprofiling and filling with compacted free-draining stone was concluded to provide fair geotechnical risk management.

P60 multipurpose slope climbing rigs were used for the GI works

However, Mott MacDonald’s analysis showed potential encroachment on third party land. Soil nailing was ruled out due to the problems anticipated from the coarse soils and high groundwater.

The team eventually selected a retention solution, comprising a 2m high gabion wall which retains Standards for Highway Works (SHW) Class 6N well-graded granular fill. It also proposed topsoil retention on the class 6N material to enable vegetation growth after seeding. A concrete cascade permits outflow of the gabion wall drainage, which captures the spring flow, the ultimate outfall of which is a pipe over the cribwork wall and into an enhanced channel.

A 750mm thick SHW Class 6G rock blanket was proposed on the lower slope to manage groundwater seepage. A 1m high gabion wall was included in the west of the site to retain an inspection path cutting. A 500m length of crest drain was to be excavated and the porous concrete pipe replaced with a twin wall plastic pipe with additional resilience in the form of an impermeable membrane on the downslope side and separator geotextile wrapping the trench. Other measures included ditch clearance and cribwork wall repairs.

Construction phase

Geotechnical risk management was recognised at tender stage on the basis of a technical and commercial split of 60% and 40%, respectively, for tender scoring. Alun Griffiths began construction in autumn 2021, with full time engineer site presence from Mott MacDonald to aid residual risk management.

Alun Griffiths South Wales operations director Mark Legge says: “The site was fairly unique with the number of constraints, including limited access, proximity to a busy trunk road and the fact that the works were on a failing slope.”

Access was formed from the toe and via a fill platform within the closed lane.

Mott MacDonald civil engineer and drainage designer Matt Butler co-supervised the construction phase, noting that “renewal of the crest drain was commenced first, and due to fines presence throughout the filter media, clean stone backfill had to be imported for the new pipework”.

Excavations for the gabion wall were formed in bays to manage temporary slope stability. A backfall on the wall blinding was formed to aid stability and direct water into the back of wall drainage – a perforated pipe with filter media wrapped in a separator geotextile to minimise fines ingress. Rodding eye accesses were used in place of chambers where possible to aid constructability.

Alun Griffiths used remote-controlled plant to compact the Class 6N backfill, limiting person-operated plant on the slope. A 150mm thick cellular topsoil retention system was installed on the backfill, with additional resilience in the form of anchor-trench embedment at the crest. In front of the wall, 0.5m of geogrid reinforced fill provides embedment and a robust inspection access.

The cascade and adjacent steps are a proprietary modular concrete stairs product, reducing the need for formwork. The step treads were infilled with concrete, and natural stone side walls were formed for the cascade. For additional sliding resistance, 25mm diameter high yield strength bars were driven into the slope and embedded within the treads. After a very dry early to mid-2022, water flow was observed in the new drainage in November 2022, after heavy rainfall.

Damaged cribwork wall elements were deconstructed to determine the reinforcement details. Surplus elements were cast for potential future works. To avoid dismantling the wall to replace damaged elements at the wall base, elements were broken back to fresh concrete, reinforcement added and formwork used to cast repairs.

The works were completed and the traffic management was removed in June 2022.

Future asset management

The project team developed the design to be as simple and easy to maintain as possible. Key objectives are ensuring free flow of drainage and serviceability of retention measures.

“As part of the geotechnical feedback report we recommended a risk-based approach to inspections, with the frequency decreasing over time to baseline DMRB CS641 (Managing the maintenance of highway geotechnical assets) standard requirements as the performance of the works is observed and response to weather events compared with the expected behaviour,” St John says.

The open cascade and discharge of water into the channel allows inspectors to confirm drainage effectiveness. Dedicated paths and inclusion of steps with guard rails allows safe access for long term inspection and maintenance of the retention measures, chambers and crest drain.

NMWTRA asset manager Stuart MacKenzie says that “the consideration given for accessing the site for routine inspections and future maintenance of the asset has set a benchmark for future schemes on the network”.

Challenges for managing the wider cutting asset include potential future instability of the ageing earthwork and cribwork wall, as well as management of slope vegetation. The simple solution implemented at the landslide is suitable for replication at other sites on the cutting, if required.

Welsh Government principal geotechnical engineer Iain McKenzie concludes that “the scheme demonstrates how easily maintainable remedial works can be incorporated into challenging earthwork sites when design teams work alongside the maintenance teams who will inherit the asset”.